Flow Elements

Water Meters

- Battery Powered Water Meter is designed to measure the velocity of a fluid in a sealed pipeline fitted with transducers.This enables calculation of flow and volume based on time of flight principle. It is a static water meter which has no moving parts to avoid wear and tear.

- Water meters is an integral and hermetically closed static water meter intended for the registration of cold and hot water consumption. ASIONIC® – 400S is constructed as a vacuum chamber of moulded composite material. Thus, the electronics are fully protected against penetration of water. This means that the meter can be work without problems. The water meter is powered by an internal lithium battery with up to 10 years lifetime. The battery can be changed by one of the Electronet’s authorised service center / personnel.

Turbine Flow Meters

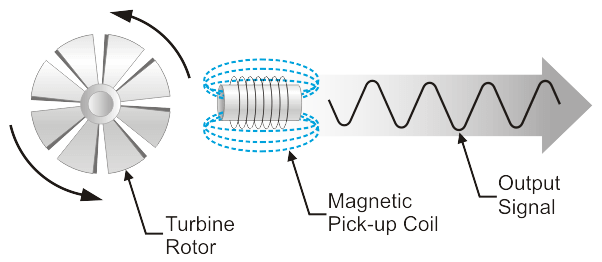

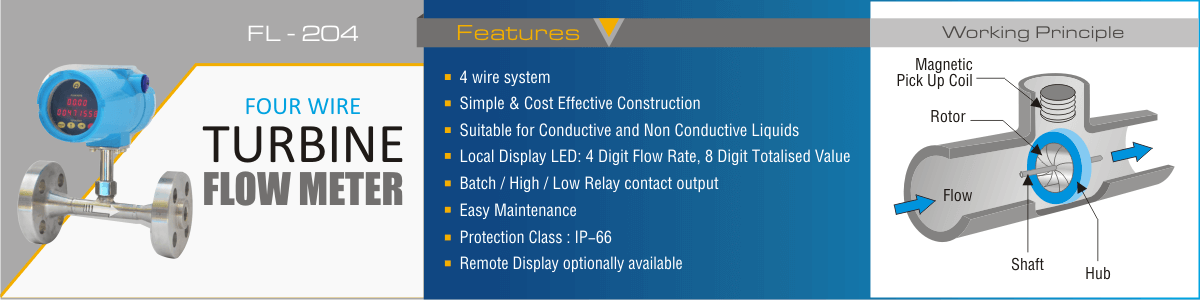

- The Turbine Flow meter is used for the measurement of liquid flow rate. It works on the principle of Turbine. A turbine flow meter is constructed with rotor and blades that use the mechanical energy of the fluid to rotate the rotor in the flow stream. Blades on the rotor are angled to transform energy from the flow stream into rotational energy. The rotor shaft spins on bearings – When the fluid moves faster, the rotor spins proportionally faster.

- The diameter of the rotar is slightly less than the inside diameter of the pipe, and its speed of rotation is proportional to the volumetric flow rate. The magnetic pick-up coil consists of a permanent magnet with coil windings which is mounted in close proximity to the rotor. As each rotor blade passes the magnetic pick-up coil, it generates a voltage pulse which is a measure of the flow rate. The total number of pulses gives a measure of the total flow.

Ultrasonic Flow Meters

- An ultrasonic flow meter is a type of flow meter that measures the velocity of a fluid with ultrasound to calculate volume flow. Using ultrasonic transducers, the flow meter can measure the average velocity along the path of an emitted beam of ultrasound, by averaging the difference in measured transit time between the pulses of ultrasound propagating into and against the direction of the flow or by measuring the frequency shift from the Doppler effect.

- Ultrasonic flow meters are affected by the acoustic properties of the fluid and can be impacted by temperature, density, viscosity and suspended particulates depending on the exact flow meter. They vary greatly in purchase price but are often inexpensive to use and maintain because they do not use moving parts, unlike mechanical flow meters.

- Electronet series ASIONIC® – 200 are micro-controller based full bore type Ultrasonic Flow Meters, specially used for various industrial applications. These flow meters accurately measures the flow rate of liquid in closed pipes.

- Due to its simple & rigid design, the flow meter is an obstruction-less & maintenance free instrument in place of conventional mechanical Flow measuring devices.

- The system is well suited to most environments. Programming of the flow meter is simple and can be accomplished with 4 keys available on instrument, It provides access to an extensive range of diagnostic information. ELECTRONET manufactures serval flow meter consoles to meet the specific requirements of various applications.

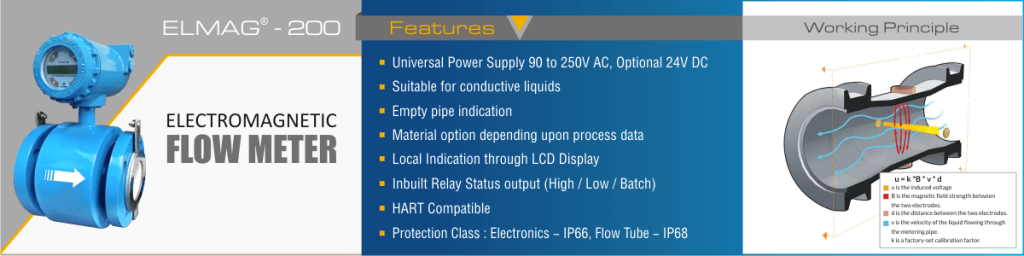

Electromagnetic Flow Meter

- Electromagnetic Flow Meters are based on FARADAY’S LAW OF INDUCTION. A magnetic field is applied to the metering tube, which results in a potential difference proportional to the flow velocity perpendicular to the flux lines. The physical principle at work is electromagnetic induction. The meter features flanged construction and is available with choice of liner and electrode material. All meters consist of a sensor and a converter that may be mounted integral to the sensor or remotely either with a field mount kit.

- These meters are also called as Magflow or, EM Flow Meters. These meters has no any moving parts in it, so these very well recommended for food grade applications like Juices, Milk, Municipal or Industrial Water etc. These meters are also suitable for liquids were there are lot of suspended particles like Sewage, Waste Water, Chemicals, Slurries etc.

- Electronet series ELMAG® – 200 are micro-controller based full bore type electromagnetic flow meters specially used for various industrial applications. These flow meters accurately measure the flow rate of conductive liquids & slurries in closed pipes.

- Due to its simple and rigid design, the flow meter is an obstruction-less and maintenance-free instrument in place of conventional mechanical flow measuring devices. The use of ‘Pulsed DC’ technology offers highest ability and better measuring accuracy in the form of electrical signal 4-20 mA DC linearly proportional to volumetric flow.

- A magnetic field is generated by the instrument in the flow tube. The fluid flowing through this magnetic field generates a voltage that is proportional to the flow velocity. Corresponding electrical output is provided with respect to measuring flow range.

- Electronet Flowmeters are calibrated at our own Water Flow Calibration Facility. It uses the primary method of measuring the water flow by gravimetric principle. The facility is designed for calibration of flowmeters under controlled and stable flow conditions.

Orifice Flange Assembly

- An orifice meter or orifice plate is a flat plate having a central hole that is placed across the flow of a liquid, usually between flanges in a pipeline. The pressure difference generated by the flow velocity through the hole enables the flow quantity to be measured.

- An orifice plate is a device used for measuring flow rate, for reducing pressure or for restricting flow (in the latter two cases it is often called a restriction plate). Either a volumetric or mass flow rate may be determined, depending on the calculation associated with the orifice plate. It uses the same principle as a Venturi nozzle, namely Bernoulli’s Principle which states that there is a relationship between the pressure of the fluid and the velocity of the fluid.

- When the velocity increases, the pressure decreases and vice versa. Orifice Flange assembly can be manufactured in size ½” to 40” for class 150, 300, 600, 900, 1500.

Venturi Meter

- A venturi meter is a flow measurement instrument which uses a converging section of pipe to give an increase in the flow velocity and a corresponding pressure drop from which the flow rate can be deduced. They have been in common use for many years, especially in the water supply industry.

- In a venturi meter, the flow velocity is measured by noting the pressure differences between the inlet and the throat of the venturi meter.

- A venturi meter can be used to measure the flow rates of all incompressible flows (gases with low pressure variations, as wells as liquids).

Spools

- We manufacture & supply upstream and down Stream pipe spools for flow meters such as, Orifice, Turbine meter & Liquid & Gas Ultrasonic meters.

- Upstream and Downstream spools will be manufactured according to international standard & with suitable Material of carbon steel ASTM 105 & Stainless steel ASTMA182F316L.

Sight Flow Indicator (Sight Glass)

- Sight Flow indicators are used to visually monitor and determine the flow of fluids. These affordable and easy-to-operate devices are installed directly in the process line and allow operators to qualitatively observe flow rate, direction, colour and clarity. The readings are then viewed through a glass viewing lens. There are two ways to deploy Sight Flow Indicators.

- Individually at vital points along fluid lines Where alterations, disruptions or contamination of fluids are supposed to have occurred or in banks, all together, where simultaneous monitoring of multiple fluid lines is necessary.