Fluenta

Fluenta

Fluenta Flare Gas Meter

Why Measure Flare and Vent Gas?

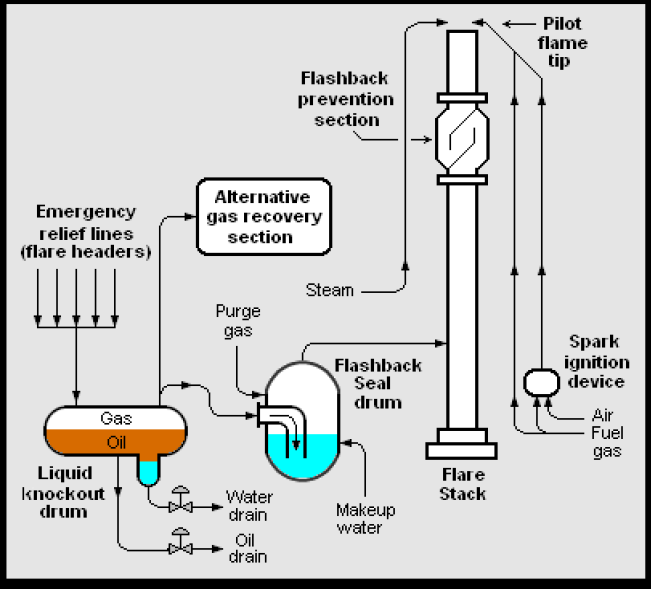

Flare and vent systems are primarily installed for safety and waste gas disposal purposes.

Flare and vent gas measurement systems are installed to monitor gas volumes for:- Legislation

- Environment

- Mass balance & flare line leaks

How can measuring flare gas save you money?

- Accurately providing flare gas figures, avoiding unnecessary fines and tax

- Identify and monitor mass balance errors

- Accurate flare gas volumes can help you understand any potential for capturing and using, or potentially selling, the associated gas.

- Understand flare gas volumes to set realistic reduction targets

Challenges in Flare Gas Measurement

- Large gas flow velocity range (0.03 – 120 m/s) – 4000:1 turndown

- Variety of pipe diameters

- Low pressure

- Variable gas composition (CO2, H2, H2O),

- Challenging process conditions

– CO2, H2S, dirt, wax, condensate

– Exposure to erosion or corrosion (exotic materials) Accuracy without pressure drop

– Non-intrusive measurement requirements

- Global fiscal requirements

- Accurate measurement (calibration, yearly maintenance)

- Certification: IECEx,ATEX,NRTL,TR-CU,INMETRO/Ingress :IP 66

- Flow Computer: Exde(ia)IICT6, Tamb: -40 °C to +60 °C (Zone 1)

- Sensors: EX ia IIC Zone 0

- Time-of-flight / Wetted Non-intrusive std.

- High Turn Down Ratio: 4000:1

- Repeatability: Better than 1%

- Resolution: 0.003 ft/s (0.0008 m/s)

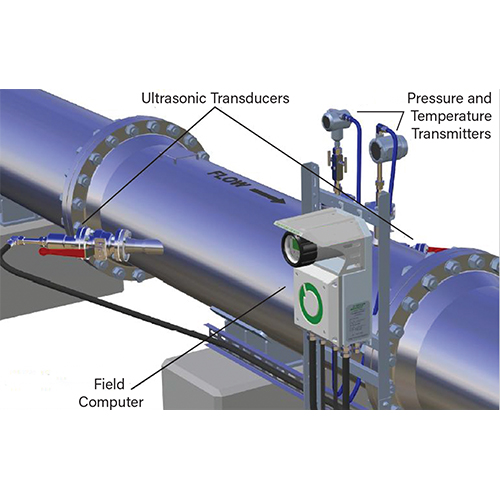

Typical flare gas meter installation

Key applications

Fluenta’s products are robust, reliable and accurate. The Fluenta flare gas meter product range supports customers with:

- Measurement of flare gas

- Monitoring flow of gas

- Environmental and regulatory compliance

Key industries

Our ultrasonic measurement transducers support industries operating in the most extreme and hostile environments on Earth, including:

For three decades we have continually pioneered flare gas measurement instrumentation that futureproofs client and regulatory needs.

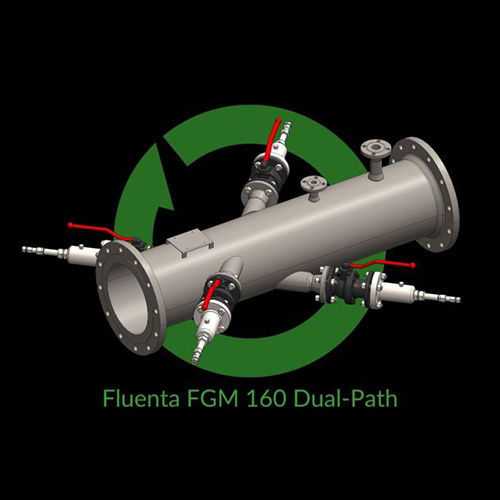

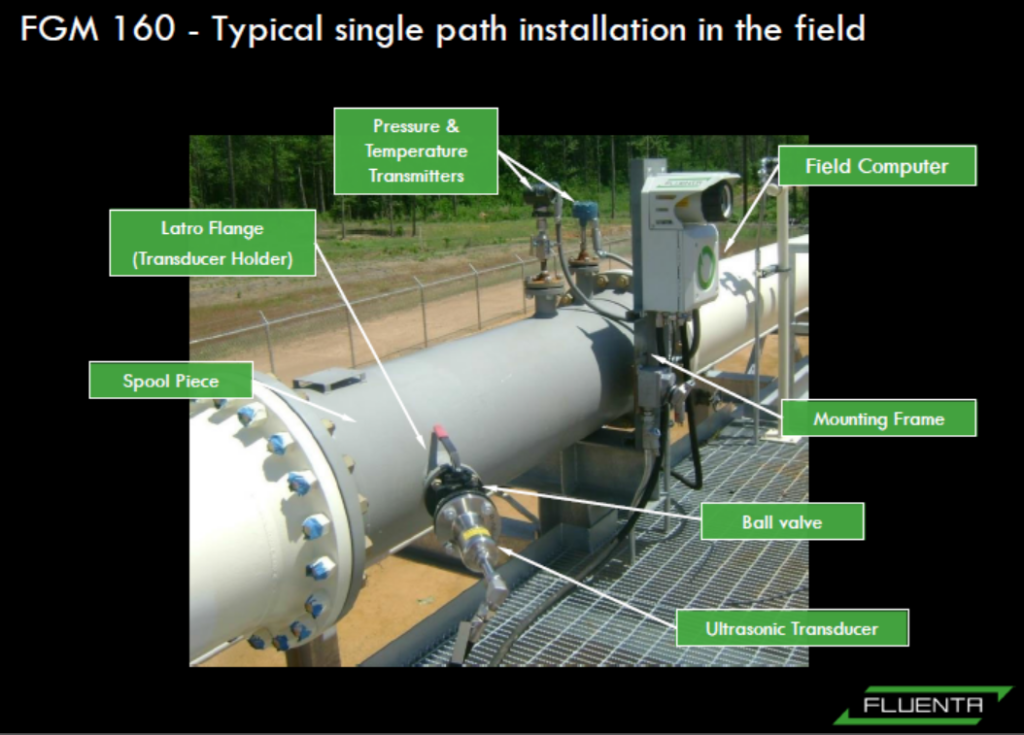

FGM 160 and FGM 160 Dual-Path

FGM 160 and FGM 160 Dual-Path

At the heart of the system is the FGM 160 flare gas meter. Designed for the most rugged environments and deployed in harsh conditions around the world, this field computer provides accurate measurement of flare gas across a wide range of operating parameters. The FGM 160 provides flow, mass flow, molecular weight and a range of other data through all commonly used industrial protocols. The FGM 160 Dual-Path provides all the advantaged of our FGM 160 system with an extra measurement path, offering increased accuracy and full redundancy.

Transducers

TFS Transducers

Fluenta’s TFS transducer range use ultrasonic technology for highly accurate measurement in a range of applications, helping you meet industry and environmental regulations.

Fluenta FlarePhase™ Transducers

Fluenta’s FlarePhase™ transducer range sets the standard for flare gas measurement. With three options, each featuring advanced technology, the Fluenta FlarePhase™ range offers operators accurate and reliable flare gas measurement in temperature and gas extremes.

UFM Manager Software

UFM Manager Software

Our easy to use software package improves setup of flow calibration, diagnostics, measurement, and security in your system – so you get better data with less effort. UFM Manager runs from any PC running Windows 10, and connects to the meter using standard cabling. Product updates mean you always have the latest features whilst licences for users and service engineers ensures only trained engineers can get access to your system.

The Fluenta product family

Our core competence is the accurate measurement of flare gas using ultrasonic techniques, which are by far the most accurate method of measuring flow. With a range of transducers for different temperatures and gas compositions, Fluenta have a product portfolio to cover almost every application.

From installation to active deployment, our highly trained staff provide on site and remote support whenever required, ensuring all our flare gas meters provide a lifetime of accurate flow measurement and management.

Download our product information

For more information, or if you would like to purchase one of our products, please get in touch by visiting our contact page.

Alternatively, click below to view the current and historical Fluenta flare gas measurement product information, data sheets and more:

Why Fluenta?

- High levels of accuracy: Uniquely Fluenta uses multiple ultrasound frequencies on one single pair of probes, delivering extremely high levels of accuracy.

- Reliability: one of the biggest challenges for flow measurement is reliability when the pipe is at extremely high or low pressure. Fluenta’s technology ensures that effective measurement is still possible in these environments.

- Trusted: Fluenta’s products have been deployed more than 1500 times and are trusted by some of the largest names in the oil and gas industry.

- Flexible: Fluenta’s non-intrusive sensors can be deployed on a wide range of pipe diameters. Additionally, the sensors do not obstruct flow. Highly accurate sensors are therefore not in the direct flow of gas, minimising exposure to flow particles , moisture, dirt or corrosive gases, delivering a longer lifecycle.

- Ease of installation and use: Fluenta deploys custom designed jigs for fast and economical product mountings. Fluenta’s product only needs around half the footprint of straight pipe in comparison to some competitors, making it ideal for complex deployments.