Level Mesurements

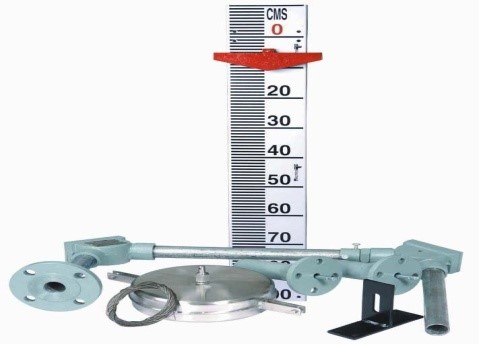

Float & Board Level Gauge

- Float and Board type Tank Level Indicator that can be used for continuous Level Measurement of all kinds of Liquids such as Petroleum Products, Food Stuffs, Edible Oil, Acid & Alkaline Solutions, Paints & Varnishes, and Liquids of high viscosity.

- Measuring Range: As per Tank Height.

- Accuracy: ±10mm Minimum Reading 10mm.

- Working Temperature: Maximum 200°C.

- Working Pressure: Atmospheric.

- Indication: Aluminium Scale Graduated in centimetres & meters.

- Scale Location: Tank Side.

Oil Level Indicator

- Oil level must be carefully monitored to ensure oil additive has been depleted due to exposure to high temperature through joints continuous movements, oil pick out with component on movement. A Lubricator is used one or more of the purpose to reduce friction, to prevent ware & tare to prevent adhesion, to aid in distributing the load to cool the moving elements& to prevent corrosion.

- Knobe type oil indicator can be used in Compressors, Gear Boxes, Pharma Machinery, SPM etc…

- L-Shape indicators are easy to install and dismantled and require no maintenance in addition to this products are higher on performance and robust & durable in nature thread connection 1/8” to ½” , Length up to 300mm.

Capacitance Level Transmitter

A capacitor is formed when a level sensing electrode is installed in a vessel. The metal rod of the electrode acts as one plate of the capacitor and the tank wall (or reference electrode in a non-metallic vessel) acts as the other plate. As level rises, the air or gas normally surrounding the electrode is displaced by material having a different dielectric constant. A change in the value of the capacitor takes place because the dielectric between the plates has changed. RF (radio frequency) capacitance instruments detect this change and convert it into a relay actuation or a proportional output signal.

- The device is independent of the dielectric constant (dc) as of a liquid conductivity of 100μS/cm and allows measurement of various liquids without the need for recalibration.

- Process connections: Flanges and threads.

- Process pressure: Vacuum to +100bar (vacuum to +1,450psi).

- Measuring range: 0.1 to 4.0m (0.3 to 13ft).

Temperature: -80 to +200°C (-112 to +392°F).

Two Wire Ultrasonic Level Transmitters

- Two wire Ultrasonic Level Transmitters specially designed for non contact type level measurement. Ultrasonic level measurement is based on the time required by ultrasonic pulses to travel from sensor & surface of liquid & back to sensor. Ultrasonic level transmitters are the best for applications such as slurries, corrosive liquids & waste water. The transmitter provides 4-20 mA DC continuous output with local indication through LCD. The measuring range is available from 0.6to 12mtrs.

- Non contact type with no moving parts.

- Local Display: LCD Display.

- Password Protection.

- Compact size & Easy Maintenance.

- Software calibration.

- Measures liquid height, distance to liquid, volume or flow in open channels.